History and origin: colloidal oatmeal (oat flour)

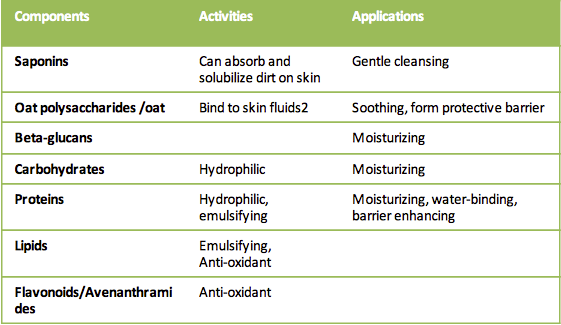

Oatmeal baths have long been recommended for people with a variety of sensitive skin conditions, providing a soothing, comforting effect. The texture of colloidal oatmeal, along with beneficial components such as proteins, lipids and saponins, make it well suited for use in moisturizers, cleansing soaps and other products that help clean, soothe and protect the skin.

The use of oats on skin care dates to ancient Egypt.(1) Whole or rolled oats were used in soothing baths. Oats used in this way did not disperse well in baths and were messy. In 1945, technological advances permitted the manufacture of colloidal oatmeal, which is prepared from de-hulled oats ground to a fine powder. The first ready-to-use colloidal oatmeal bath treatment was used at the Mayo Clinic in 1945. Colloidal oatmeal retains the moisturizing effects of the whole oat grain but disperses more easily in bath water and can also be added to creams and lotions for use in topical products.

Processing

The manufacturing process for colloidal oat is a process achieved without the use of chemical solvents. Oat grains with high protein content are selected for colloidal oat production and are non-GMO. The production of the colloidal oatmeal used in Aveeno® products comes from a dedicated production line assuring high quality standards.

Composition and activity

Colloidal oatmeal is obtained from grinding the whole seed. All components are preserved: approximately 60% polysaccharides, 10-18% proteins (glutaminic acid-aspartic acid...), 5% lipids (phospholipids, sterols...), enzymes, vitamins, flavonoids and phenolic acids (avenanthramides). (18)

Oatmeal can help restore normal pH in skin conditions where pH has increased. In this setting, it acts as a buffering agent, thereby aiding in the maintenance of a healthy skin barrier.(3,4)

The moisturizing properties of colloidal oatmeal are provided by a hydrophilic film that forms at the skin surface. It consists of humectant and water-binding constituents and lipids.

Starches are important constituents of colloidal oatmeal. They are highly hydrophilic and can absorb large quantities of water.(5,6) Proteins contained in colloidal oatmeal further contribute to its water affinity.(6,7) The unique lipid composition of colloidal oatmeal(7) participates in the formation of a film at the skin’s surface.(4,8) Oat triglycerides and phospholipids, as well as oleic, linoleic and linolenic acids, which are contained in oat lipids are important stratum corneum components.(8)

Colloidal oatmeal provides gentle cleansing without loss of the skin’s moisture content. It thus helps prevent skin dryness and the clinical signs associated with skin dryness.(4)

Table 1: Components, Activities, Applications / Contents of Oatmeal

Oat extracts

Oats contain a number of active compounds—saponins, flavonoids, minerals, alkaloids, steroidal compounds, vitamins and carotene—as well as the highest protein (15 to 20%) and lipid (3 to 11%) content of any grain. The lipid component is protected from oxidation by natural antioxidant compounds such as the avenanthramides.

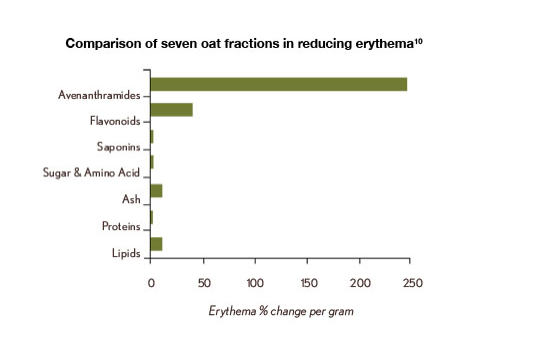

Avenanthramides are the main polyphenolic antioxidants in oat grains, demonstrating greater antioxidant activity (10-to 30-fold greater) than that of the other oat phenolic compounds such as vanillin or caffeic acid and five-fold greater than that of oat flavonoids. (9,10)

This antioxidant activity has been linked to structural factors such as the presence of amine bonds and number and position of hydroxyl groups. Vollhardt et al (10) compared the functional properties of seven oat fractions (avenanthramides, flavonoids, saponins, sugar and amino acids, ash, proteins and lipids) in reducing UV-induced skin erythema, as measured by change in skin color, 24 hours after application and found avenanthramides to have the greatest activity against erythema.

Comparison of seven oat fractions in reducing erythema (10)

Avenanthramides also demonstrate potent anti-irritant properties. The anti-irritant effect may result in decreased contact hypersensitivity. It may also reduce the scratching-induced secondary irritation that can occur in extra dry, itchy skin, preventing disruption of the skin barrier function.(11)

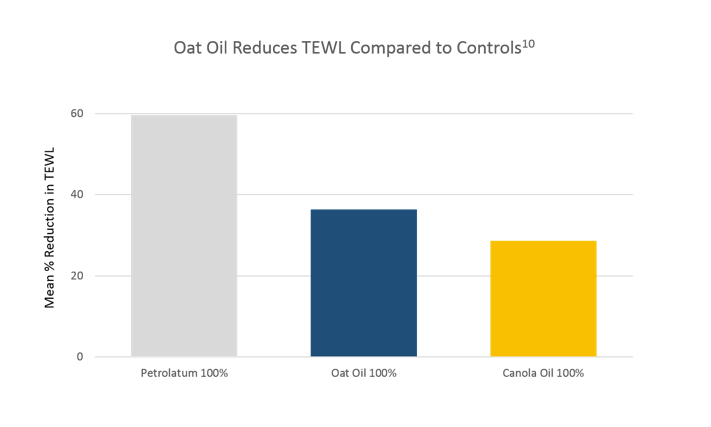

Oat oil is a separate component from avenanthramides and colloidal oats. Oats are generally regarded as having the highest lipid content of any cereal grain (~ 7% to 10%) and as an excellent source of unsaturated fatty acids.(11-13) Oat oil is a mixture of lipid components, each with its own biological properties. When fractionated, oat oil is found to be composed of around 50% triglycerides, 14% mono- and diglycerides, and 10% free fatty acids, with smaller amounts of sterols, phosphatidyl choline, phosphatidyl ethanolamine, and other compounds, all of which are affected to some extent by cultivation conditions, plant genetics, and the method of lipid extraction.(11-13) Oat lipids contain about 80% unsaturated fatty acids, which in turn are about 42% to 52% linoleic acid, Lineolic acid has been shown effective in reducing transepidermal water loss and restoring the skin permeability barrier. (14-15)

Formulation

The physical and chemical properties of oatmeal are unique and require extensive knowledge in formulation in order to ensure the uniform dispersion of colloidal oatmeal, maintain the foaming performance of colloidal based cleansers and secure preservation of formulas. Scientists for the Aveeno® Brand have years of experience developing products with oatmeal to deliver effective, stable and aesthetically-pleasant product formulas containing oatmeal.

References

1. Miller A. Oat derivatives in bath products. Cosmet Toiletries 1979;94:72-80.

2. Rinaldi, Fabio, Rigano, Luigi. Colloidal Oatmeal, Characteristics, Properties, Clinical Applications. Scientific Library of Rydelle Laboratories; 35-43.

3. Johnson & Johnson, Skillman, NJ; data on file.

4. Grais ML. Role of colloidal oatmeal in dermatologic treatment of the aged. AMA Arch Derm Syphilol 1953; 68:402-407.

5. Paton D. (1986) Oat starch: physical, chemical and structural properties. In: Webster FH, ed., Oats: Chemistry and Technology. Saint Paul, MN, American Association of Cereal Chemists, Inc.93-120.

6. Rawlings AV et al. (2002) Humectants. In: Skin Moisturization. Leyden and Rawlings Eds. New York, NY. Marcel Dekker, Inc.; 245-266.

7. Peterson DM, Brinegar AC. Oat storage proteins. In: Webster FH, ed. Oats: Chemistry and Technology. St. Paul, MN: American Association of Cereal Chemists, Inc. 1986;153-203.

8. Zhou M, Robards K, Glennie-Holmes M et al. Oat lipids. J. Am Oil Chem Soc. 1999;76:159-169.

9. Meydani M. Potential health benefits of avenanthramides of oats. Nutr Rev 2009;67(12):731-735.

10. Vollhardt J, Fielder DA, Redmont MJ. Identification and cosmetic application of powerful anti-irritant constituents of oat grain. XXI IFSCC International Congress 2000, Berlin. Proceedings; 395-402.

11. Banas A, Debski H, et al. Lipids in grain tissues of oat (Avena sativa): differences in content, time of deposition, and fatty acid composition. Journal of Experimental Botany, Vol 58, No. 10, pp. 2463-2470, 2007.

12. Youngs VL. Oat Lipids. Cereal Chem. 55(5):591-597.

13. Holland JB, Frey KJ, Hammond EG. Correlated responses of fatty acid composition, grain quality and agronomic traits to nine cycles of recurrent selection for increased oil content in oat. Euphytica 122: 69-79, 2001.

14. Ziboh VA, Miller CC, Cho Y. Metabolism of polyunsaturated fatty acids by skin epidermal enzymes: generation of anti-inflammatory and antiproliferative metabolites. Am J Clin Nutr. 2000; 71 (suppl): 361S- 366S.

15. Potter RC, Castro JM, Moffatt LC, inventors; Nuture, Inc, assignee. Oat oil compositions with useful cosmetic and dermatological properties. US Patent 5620692. April 15, 1997.